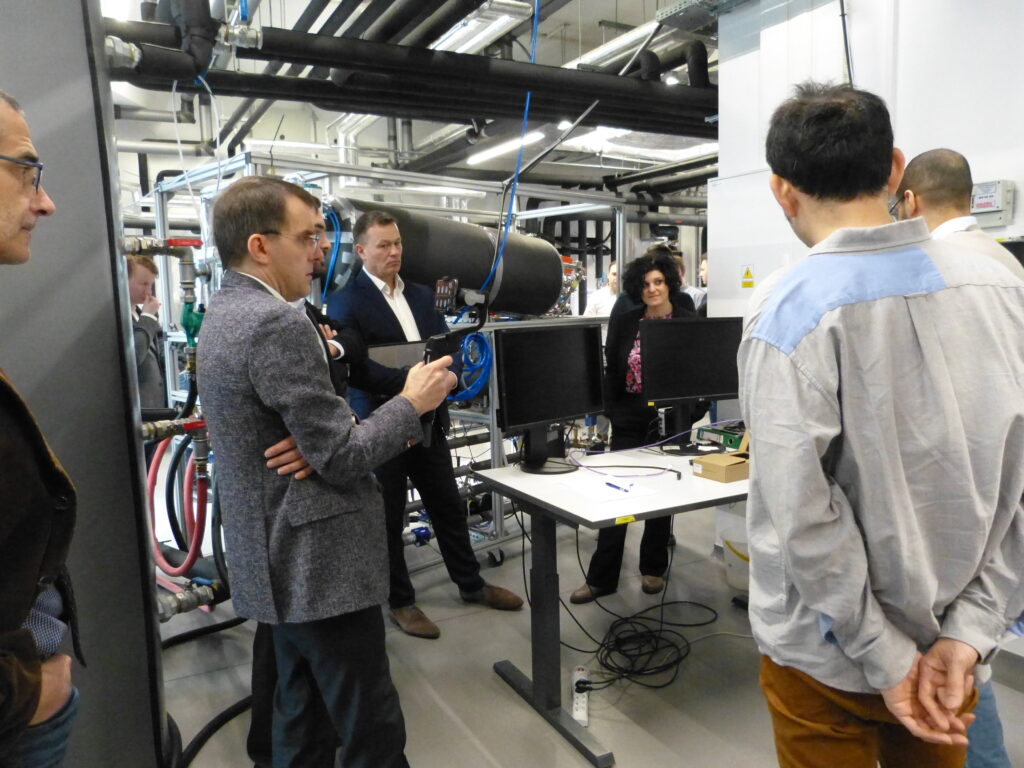

With the project nearing completion, we explored the workshop at the Kezo Live-in Lab on 18 March. It was our last live-in lab visit, and the workshop was a great success. Local stakeholders were present at the event and at the visit.

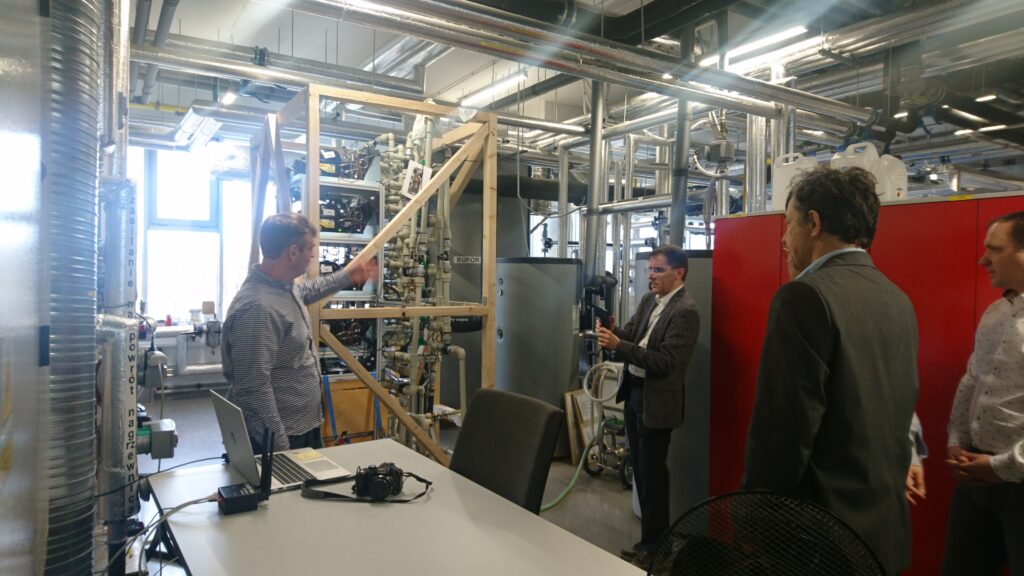

The main objective of this Live-in Lab was to test the performance of the developed enabling technologies, control system and algorithms within the integrated energy system and their cooperation with other technologies (heat/cold sources and storage) under controlled conditions and in coordination with the selected technologies for heat and cold generation already installed.

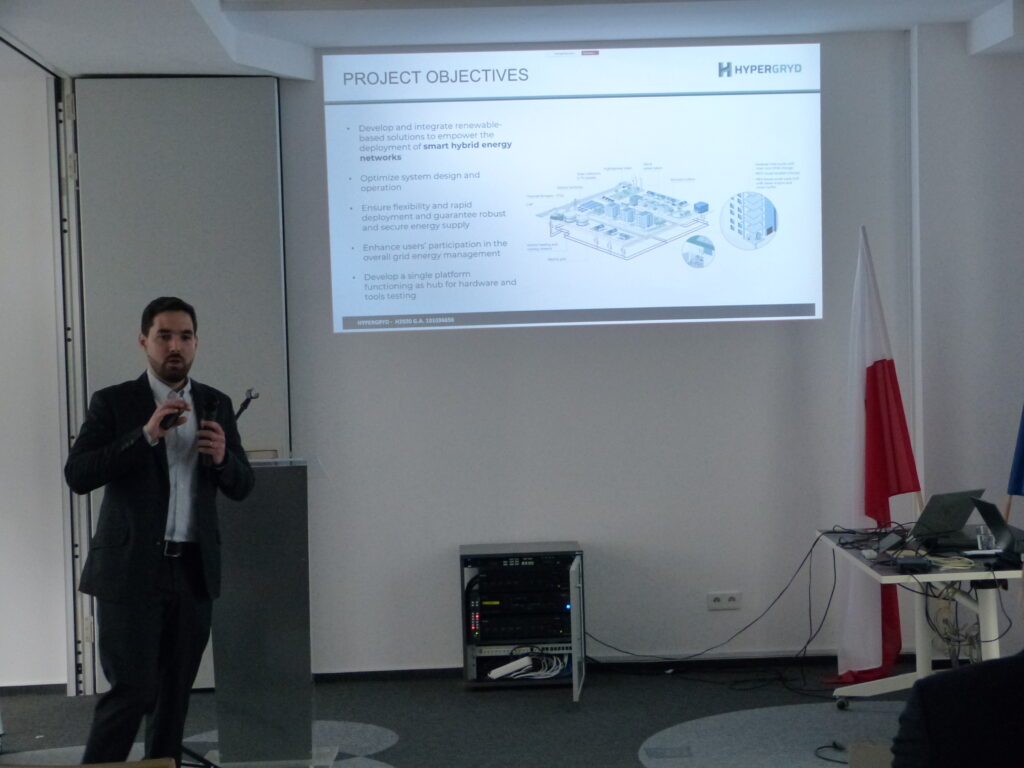

During the workshop, the Hypergryd team explained in detail the work done by the different partners in the live-in.

First, David Verez, who represented ARCbcn as the project coordinator, was introduced by Sebastian Bykuc.

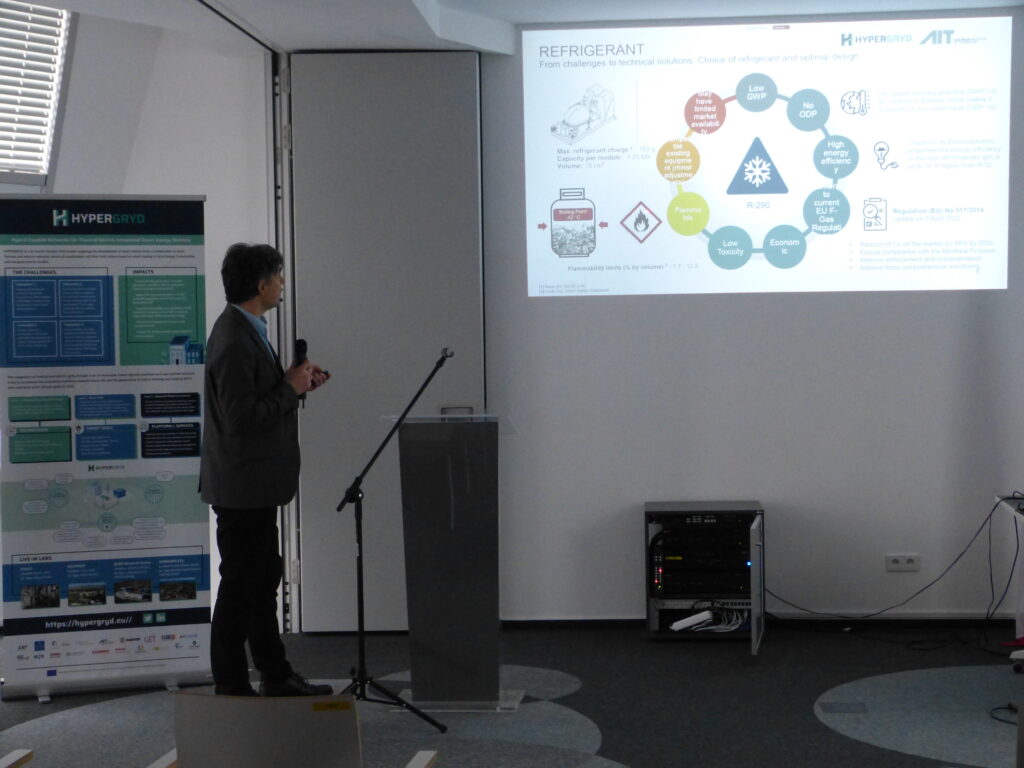

Thereafter, Christoph Reichl (AIT), Valeria Palomba (CNR-ITAE), and Mustapha Habib (KTH) explained the new enabling technology implemented in the Kezo Live-in Lab with sorption technology, HP with PCM scenarios, and IoT control systems to demonstrate the flexibility of the solutions.

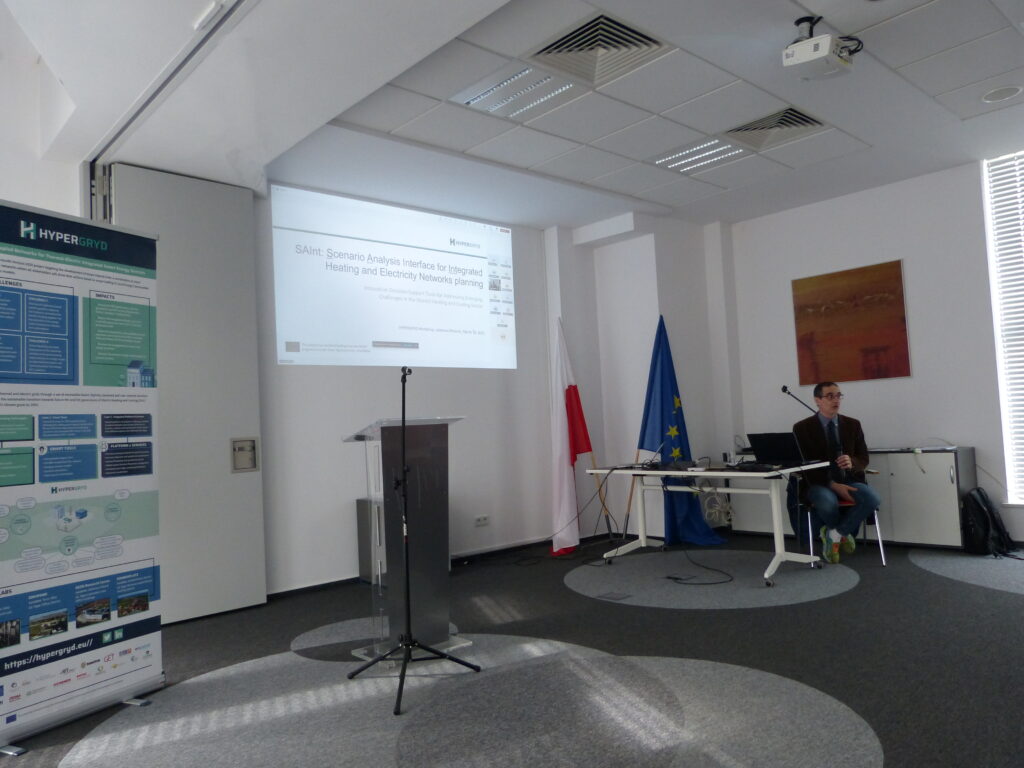

Jorge Leao (IDP) explained the BIM/GIS tool and HYPERGRYD platform for the design and layout of DHC networks and the visualisation of operational parameters in the block of simulation tools for district heating. Nicola Zaccareli (encoord) described the work done in the Kezo Live-in Lab using the scenario analysis interface for planning integrated heat and power (SAInt) grids. Christian Doczekal (GET) spoke about the Exergoeconomic Optimization tool, which is key to the economic integration of RES in Kezo DHC Networks.

The PAS of the KEZO Research Centre consists of three buildings linked into one system. The cooling and heating system consists of four main lines connecting all buildings, with heat and cold sinks and sources located along the main lines. One feature is the possibility of testing different thermal levels of the users (20/35°C or 40/60°C). Each building has its ventilation system with a ventilation unit where heat exchangers (up to 90 kWth) are fed from the main heating and cooling lines.

We visited the adsorption chiller and photovoltaic plant integrated with HYPERGRYD technologies. We also saw how the control and management software connects with HYPERGRYD’s ICT tools.

This Live-in lab proposes to reproduce and test the technologies applied with the developed and optimised algorithms in small district heating systems with a couple of small tertiary buildings.

We all appreciated the work done, and the stakeholders had the opportunity to ask questions and express interest in the applied solutions.