FCC Medio Ambiente (FCCMA) is a leading company in the waste management and treatment sector in Spain. As a member of the Salamanca Hub4Circularity within the framework of the United Circles (UC) project, FCCMA will focus on the innovative transformation of waste into valuable resources, promoting the circular economy in urban and industrial environments.

Specifically, FCCMA’s initiative aims to convert waste streams currently deposited in landfills into biofuel, thereby reducing the total volume of waste and enabling energy recovery from organic waste.

Therefore, FCC Medioambiente’s main objectives in order to achieve this goal focus on three main lines of action.

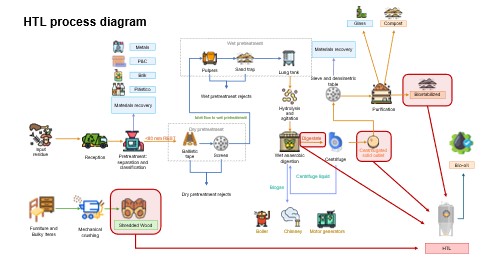

1. Development of Hydrothermal Liquefaction (HTL) technology

A thermochemical technology capable of transforming wet organic waste directly into raw material for biorefineries, without the need for energy-intensive drying processes.

Hydrothermal liquefaction (HTL) is a thermochemical process that converts biomass into liquid fuel by degrading biomass waste in an aqueous medium by subjecting it to pressure and temperature close to the critical conditions of water (374ºC and 22.1MPa).

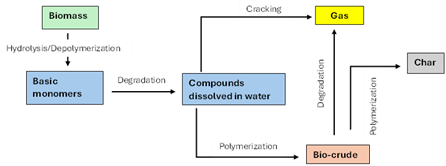

The HTL process is divided into several phases:

- Decomposition or breakdown of organic matter compounds through hydrolysis and/or depolymerisation reactions, due to the high pressure and temperature of the water, which promotes the fracture of hydrogen bonds within macromolecules. This generates monomers and simpler structural units.

- Degradation or decomposition of the monomers that have been formed, obtaining water-soluble intermediate compounds, due to cleavage, dehydration, decarboxylation, deamination and cracking reactions. Along with the removal of oxygen in the form of H2O and CO2 through dehydration and decarboxylation mechanisms, respectively. This allows the bio-crude obtained to have low oxygen content compared to bio-crude obtained by pyrolysis.

- Repolymerisation through condensation and cyclisation reactions, which produces water-insoluble products: bio-crude and bio-char.

The result of this process is biomass transformed into four fractions:

- A carbonaceous solid called hydrochar

- A bio-oil

- An aqueous phase containing polar organic components

- A gaseous stream more or less rich in methane and hydrogen

HTL is considered one of the most promising technological avenues for recovering value from waste streams that are currently not treated.

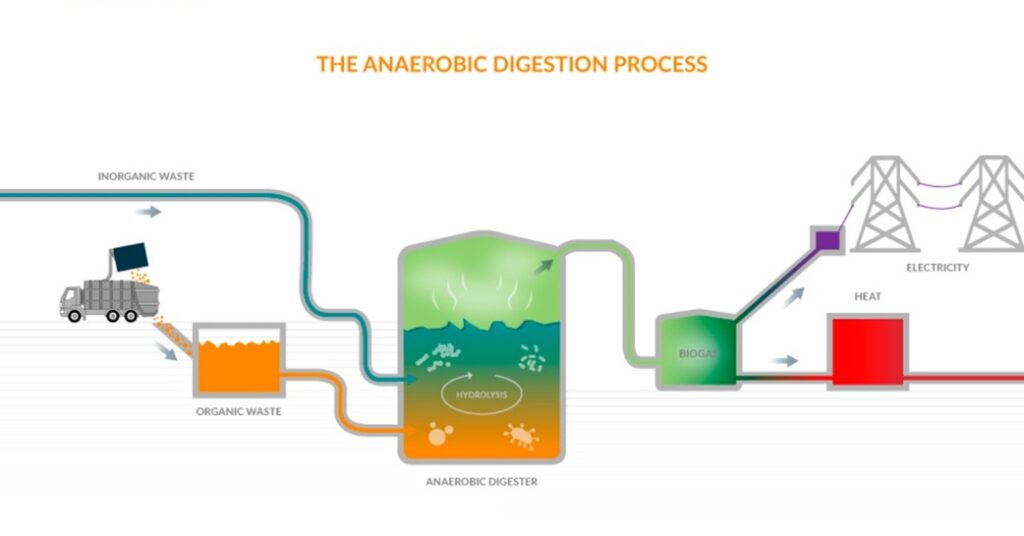

2. Study of anaerobic digestion

The anaerobic digestion process allows biogas to be obtained through the decomposition of organic matter in the absence of oxygen. The objective of this study is to treat water with a high organic load obtained during the development of different processes carried out at the plant, to carry out fermentation that allows methane to be obtained, which is then used to generate energy.

The methane generated will be used as fuel to power a cogeneration engine that will transform it into energy, which will be used to supply electricity to the plant. This allows for the creation of a self-sustaining closed circuit of energy production and consumption, which can even be sold if there is a surplus that is not consumed in the plant’s processes.

In this case study, the resource to be used as raw material for obtaining biogas will be digestate press liquid, leachate from the reject dam, and leachate from composting tunnels.

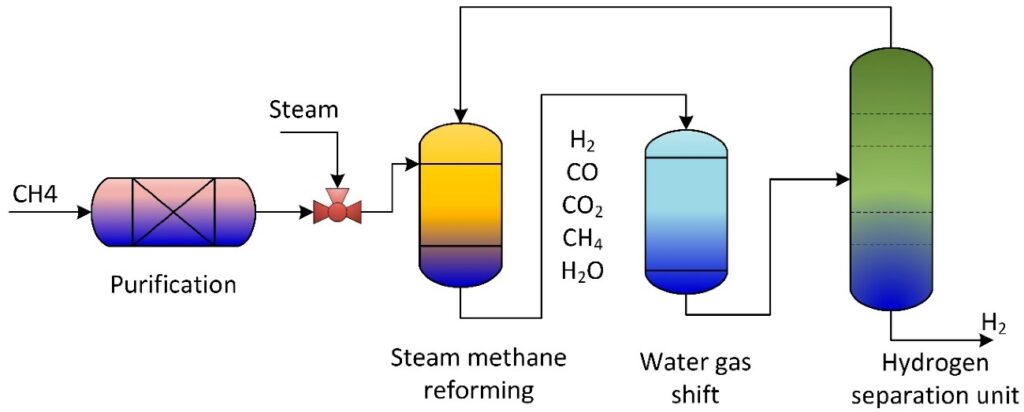

3. Innovative study of the biological methanation process

The methanation process is the method of obtaining methane, which is achieved in the plant through two main sources: fermentation derived from anaerobic digestion and the landfill degassing process. In the latter, all the biogas generated in the waste deposit is collected, resulting from the decomposition of organic matter that remains buried and begins to ferment in anaerobic conditions, releasing methane.

The study aims to optimise the production process of biomethane from landfill gas and the plant’s digesters.

Written by FCC Medio Ambiente