The construction industry has long been associated with high material consumption and significant waste generation. But a new vision is taking shape; one that transforms construction and demolition waste (C&DW) into high-performance, sustainable building materials. At the heart of this transformation is the Ankara Hub, hosted by Ekodenge and developed under the United Circles project.

In the webinar, titled “Urban C&DW Technologies for 100% Upcycled Building Construction Value Chain,” held on February 27, brought together industry leaders, researchers, and innovators. The evento showcased Türkiye’s growing leadership in circular construction, spotlighting breakthrough innovations aimed at achieving zero-waste, fully upcycled construction value chain.

A Zero-Waste Vision

The Ankara Hub is designed to achieve a 100% recycling rate of urban C&DW by leveraging cutting-edge technologies and fostering strong cross-sector collaboration. Its mission is clear: transition the construction industry from linear to a circular model – where materials are continuously reused, environmental impacts are minimized, and buildings are designed with their full life cycle in mind.

This transformation is not just about reducing waste. By turning what was once discarded into valuable inputs for next-generation construction materials, the Hub is proving that circularity is not only posible but practical. Several innovations are already being piloted and scaled, signaling that this vision is becoming a tangible reality.

Smart Technologies Driving Change

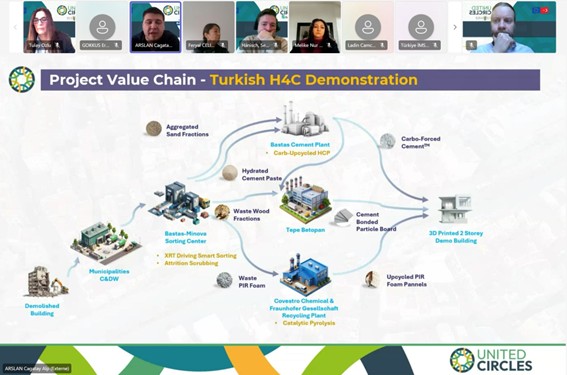

At the core of the Turkish H4C are advanced technologies that redefine how we perceive and utilize waste:

- X-Ray Transmission (XRT)-Based Smart Sorting (MINOVA) An advanced system that enables precise separation of materials such as concrete, wood, and metals. Supported by rotary breakers and attrition scrubbers, it ensures cleaner and more consistent feedstocks for new material production.

- Carbonated Blended Cement (BAŞTAŞ Çimento) Hydrated cement paste recovered from concrete waste is carbonated in industrial reactors to form low-carbon blended cement. This process significantly reduces CO₂ emissions and raw material extraction

- Two-Storey 3D-Printed Building (First of Its Kind in Türkiye) Using carbonated cement, a two-story building Will be constructed via 3D printing—demonstrating the potential of recycled materials in modern architectural applications.

- Cement-Bonded Particle Boards (TEPE BETOPAN) By integrating up to 40% recycled wood and cementitious waste, the company will improve material strength, reduce carbon emissions, and lower reliance on virgin resources.

- Polyurethane Recycling via Catalytic Pyrolysis (Covestro AG & Fraunhofer Gesellschaft) This novel method recovers high-value compounds from polyurethane foam waste which is very difficult to recycle. A pilot plant with a 10 kg/hour capacity is paving the way for industrial-scale applications in insulation material reuse.

Real Impact for a Circular Future

Ankara H4C ecosystem is more than a set of acyivities; it is a model for how urban transformation, environmental goals, and industrial innovation can converge. It tackles critical challenges including:

- Reducing reliance on landfilling

- Improving earthquake-resilient construction in urban areas

- Lowering the carbon footprint of the built environment

- Promoting cross-industry collaboration and data-driven innovation

By integrating AI, advanced Smart sorting systems, and low-emission manufacturing, Ankara Hub demonstrates that circular construction is not only environmentally necessary but also economically viable.

Built for Replication

The solutions developed at Ankara Hub are are scalable and adaptable — not just for Türkiye, but for any urban region facing challenges with waste and sustainability. Theese solutions serve as blueprints for other hubs in the United Circles network and beyond.

Looking Ahead

United Circles extends its sincere thanks to all partners driving this transformation: BAŞTAŞ Çimento, MINOVA, TEPE BETOPAN, Covestro AG, Fraunhofer Gesellschaft, and Ekodenge. Their combined expertise is shaping the future of construction through circularity As this journey continues, the Ankara Hub—hosted by Ekodenge—will remain a living demonstration site and an open innovation platform, inspiring future-ready solutions for a truly sustainable, zero-waste built environment.